Understanding Condenser Vacuum Pump Operations

Ever wondered how power plants maintain efficient steam cycles? Or how certain industrial processes achieve the low pressures needed for specific operations? The answer often lies in the ingenious mechanism of the condenser vacuum pump. These essential pieces of equipment play a critical role in a variety of applications, from power generation to chemical processing, by removing non-condensable gases and maintaining a vacuum within a condenser.

The principle behind a condenser vacuum pump's operation is surprisingly straightforward yet remarkably effective. Essentially, these pumps function by extracting air and other non-condensable gases from a condenser, thus lowering the pressure within. This reduced pressure environment allows steam to condense more efficiently, leading to improved energy efficiency and overall system performance. Understanding the nuances of condenser vacuum pump functionality is crucial for optimizing various industrial processes.

The development of condenser vacuum pumps is intertwined with the advancement of steam engine technology. As engineers sought to improve the efficiency of steam cycles, they realized the importance of maintaining a vacuum in the condenser. Early designs utilized simple reciprocating pumps, but as technology progressed, more sophisticated methods, such as liquid ring pumps and steam ejectors, emerged to meet the increasing demands of industrial applications. These advancements have allowed for greater precision and efficiency in controlling condenser pressure, leading to significant improvements in various processes.

The importance of the condenser vacuum pump working principle cannot be overstated. In power plants, maintaining a low condenser pressure directly translates to higher power output and reduced fuel consumption. In other industrial settings, these pumps facilitate crucial processes like distillation and drying by creating the necessary low-pressure environment. Failures or inefficiencies in condenser vacuum pump operation can result in significant energy losses, reduced production capacity, and even equipment damage.

One of the primary issues related to condenser vacuum pump operation is maintaining its performance over time. Factors such as wear and tear, seal degradation, and improper maintenance can negatively impact the pump's ability to maintain the desired vacuum level. Regular inspection, preventative maintenance, and timely repairs are essential to ensure reliable and efficient operation. Troubleshooting techniques often involve analyzing pressure readings, checking for leaks, and inspecting pump components for damage.

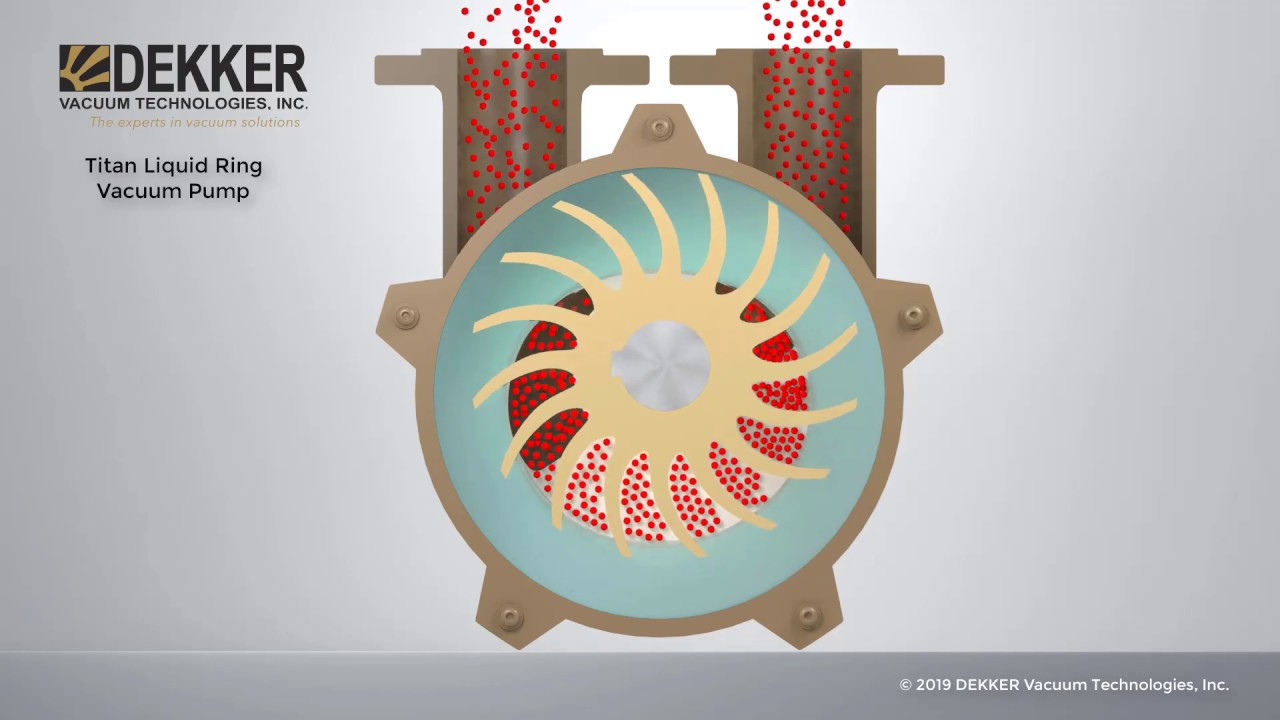

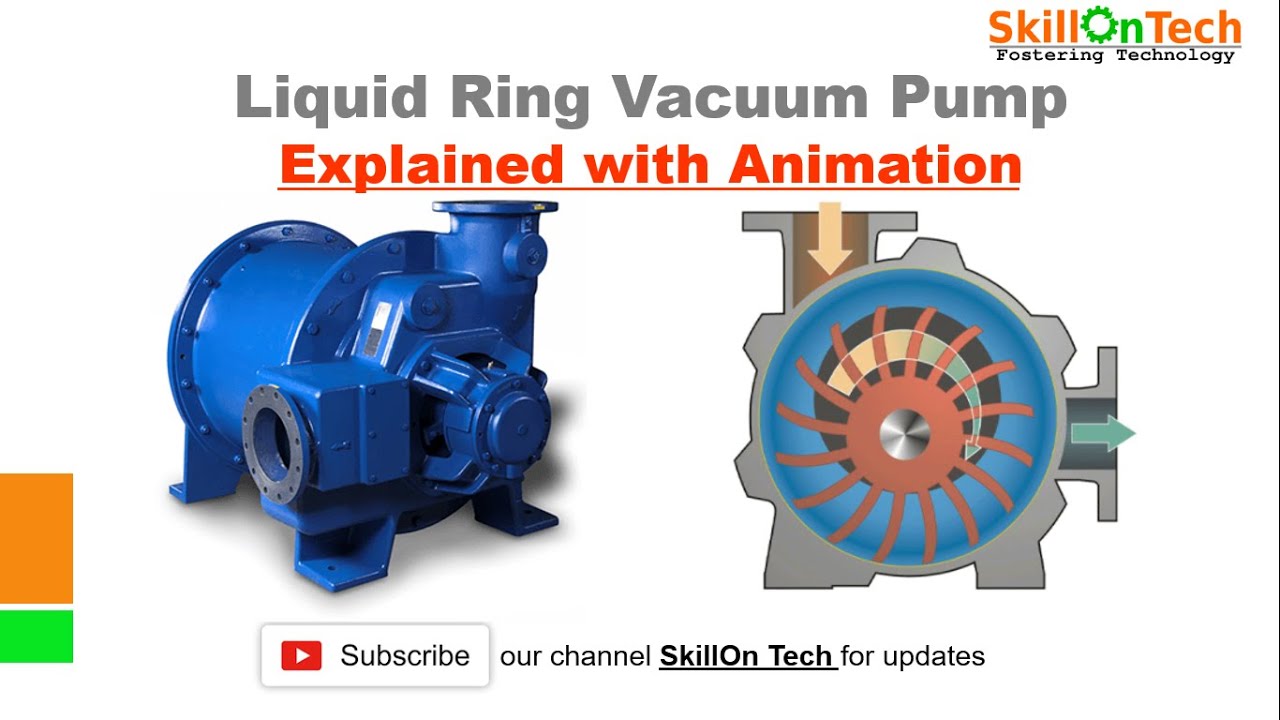

Different types of condenser vacuum pumps exist, each with its own mechanism. Liquid ring vacuum pumps use a rotating impeller and a liquid sealant to create the vacuum. Steam jet ejectors, on the other hand, utilize the Venturi effect to draw out non-condensable gases. The selection of the appropriate pump depends on the specific application and the required vacuum level.

Benefits of effective condenser vacuum pump operation include increased power plant efficiency, improved process performance in industrial applications, and reduced energy consumption. For example, in a power plant, a well-maintained condenser vacuum pump can significantly improve the turbine's efficiency by lowering the backpressure on the exhaust steam.

Advantages and Disadvantages of Condenser Vacuum Pumps

| Advantages | Disadvantages |

|---|---|

| Increased energy efficiency | Potential for seal leaks and maintenance requirements |

| Improved process performance | Can be noisy during operation |

| Reduced fuel consumption | Requires a stable water supply (for liquid ring pumps) |

Best practices for implementing condenser vacuum pumps include regular maintenance, proper installation, careful selection based on application requirements, and routine performance monitoring. Furthermore, ensuring adequate cooling water supply for liquid ring pumps is crucial for their efficient operation.

Frequently asked questions about condenser vacuum pumps often revolve around troubleshooting common issues, maintenance procedures, selection criteria, and the different types of pumps available. Understanding these aspects is essential for ensuring the optimal performance of condenser vacuum pump systems.

In conclusion, the condenser vacuum pump working principle is a critical element in various industrial processes, particularly in power generation and chemical processing. By understanding its operation, benefits, and potential challenges, engineers and operators can optimize system performance, minimize energy consumption, and ensure the reliability of their equipment. The future of condenser vacuum pump technology lies in developing more efficient and sustainable designs that can further enhance industrial processes and contribute to a greener future. Continuous improvement and innovation in this field are essential for meeting the evolving demands of modern industry and addressing the challenges of a changing world. Remember, a well-maintained and properly functioning condenser vacuum pump is a key factor in optimizing system efficiency and reducing operational costs, so prioritize its care and operation within your industrial processes.

Front terrace facades transforming homes

Taming the beast your guide to truck wiring harness kits

Decoding aarp medicare part b costs