Revolutionizing Industrial Efficiency: Impeller Repair Near Me

Downtime is the enemy of any industrial operation. When critical equipment fails, production grinds to a halt, impacting revenue and deadlines. One often-overlooked component crucial to various industrial processes is the impeller. These rotating devices, found in pumps, compressors, turbines, and more, are subjected to constant stress and wear, making impeller repair a critical service. Finding reliable "impeller repair near me" services is vital for minimizing downtime and ensuring optimal equipment performance.

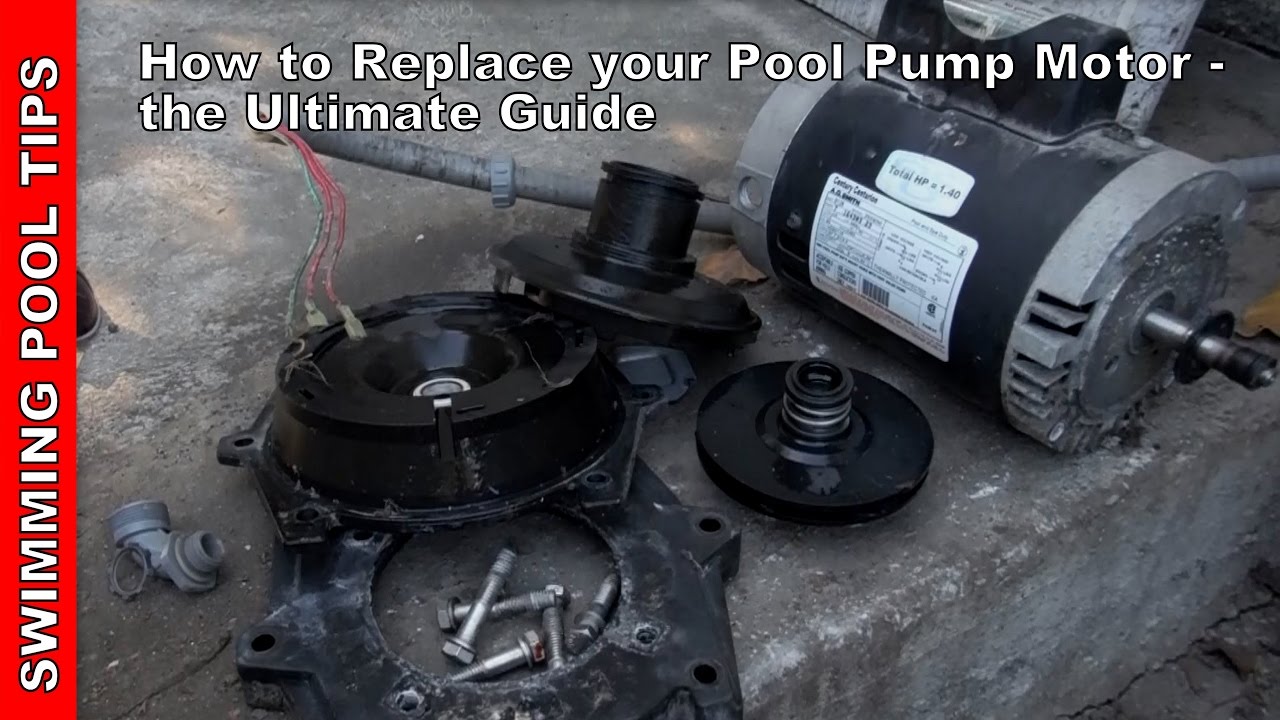

Imagine a scenario where your industrial pump suddenly malfunctions. Production slows, and you're scrambling to identify the problem. Upon inspection, a damaged impeller is revealed. This seemingly small component can cause significant disruption. This is where the importance of accessible and efficient "impeller repair near me" services becomes paramount. Quick access to local repair expertise can dramatically reduce downtime and get your operations back on track.

The history of impeller repair is intertwined with the development of industrial machinery. As impellers became integral to pumps, turbines, and other critical equipment, the need for specialized repair services emerged. Early repair techniques were often rudimentary, involving on-site patching and welding. However, as technology advanced, so did impeller repair techniques. Today, sophisticated methods like laser welding, dynamic balancing, and non-destructive testing ensure precise and durable repairs.

The importance of "impeller repair near me" services cannot be overstated. A damaged impeller can lead to decreased efficiency, increased energy consumption, and even catastrophic equipment failure. Localized repair services minimize transportation costs and time, allowing for faster turnaround times and quicker resumption of operations. Moreover, a local service provider can offer valuable insights into preventative maintenance and optimize impeller performance for your specific application.

Finding "impeller repair near me" services has become increasingly streamlined in the digital age. Online search engines and specialized directories allow businesses to quickly identify qualified repair shops in their vicinity. It's crucial to choose a service provider with a proven track record of expertise and a commitment to quality workmanship. When searching, consider factors like experience with your specific equipment type, certifications, and customer reviews.

Impeller repair services encompass a range of procedures designed to restore damaged or worn impellers to their optimal operating condition. These services typically include inspection, cleaning, crack repair, welding, balancing, and surface treatment. Some specialized services may also offer performance upgrades and coatings to enhance durability and efficiency.

Benefits of local impeller refurbishment include reduced downtime, lower transportation costs, and readily available expertise. For example, a manufacturing plant experiencing pump failure due to a damaged impeller could quickly locate a local repair service, minimizing production losses. Another example is a power generation facility requiring emergency impeller repair for a turbine. Local services enable faster response times and prevent extended outages.

An effective action plan for impeller repair involves regular inspections, proactive maintenance, and having a contingency plan in place for emergencies. Establish a relationship with a reputable local impeller repair service and schedule regular assessments to identify potential issues early on. This proactive approach can prevent costly downtime and extend the lifespan of your equipment.

Advantages and Disadvantages of Local Impeller Repair

| Advantages | Disadvantages |

|---|---|

| Reduced Downtime | Potential limitations in specialized services for highly complex repairs. |

| Lower Transportation Costs | Availability might be limited in certain remote areas. |

| Readily Available Expertise | Price variation between different local providers. |

Best practices for implementing "impeller repair near me" strategies include: regular inspections, establishing a preventative maintenance schedule, selecting a qualified local repair partner, maintaining clear communication with the service provider, and documenting all repairs and maintenance activities.

Frequently Asked Questions about Impeller Repair Near Me:

1. How do I find a reputable impeller repair service near me? - Use online search engines, industry directories, and seek recommendations from other businesses.

2. What factors should I consider when choosing a repair provider? - Look for experience, certifications, and customer reviews.

3. How much does impeller repair typically cost? - Costs vary based on the extent of damage, impeller size, and the service provider.

4. How long does impeller repair usually take? - Turnaround time depends on the complexity of the repair and the service provider's workload.

5. What are the common causes of impeller damage? - Common causes include cavitation, erosion, corrosion, and foreign object impact.

6. Can impellers be repaired on-site? - Some minor repairs can be performed on-site, but major repairs typically require specialized equipment and facilities.

7. How can I prevent impeller damage? - Proper maintenance, including regular inspections and cleaning, can help prevent impeller damage.

8. What are the signs of a damaged impeller? - Signs include decreased pump performance, unusual vibrations, and strange noises.

Tips and tricks for impeller repair near me include building relationships with multiple service providers, negotiating service contracts, and keeping spare impellers on hand for critical equipment.

In conclusion, "impeller repair near me" services are indispensable for maintaining industrial efficiency and minimizing downtime. Rapid access to local expertise enables quick repairs, reduces transportation costs, and facilitates proactive maintenance strategies. By understanding the importance of impeller maintenance, implementing best practices, and establishing a strong relationship with a qualified repair provider, businesses can ensure optimal equipment performance, minimize disruptions, and improve overall operational efficiency. Take proactive steps today to identify qualified impeller repair services in your area and develop a comprehensive maintenance plan to protect your critical equipment and ensure long-term productivity. Don't wait for a critical failure to disrupt your operations; be prepared with a plan that prioritizes efficiency and minimizes downtime. Contact local impeller repair specialists today for a consultation and assessment.

The resonant laughter exploring the world of musical dad jokes

Unlocking value your guide to the used toyota rav4 hybrid

Board shorts the ultimate guide for men