Metric vs Standard Bolts Decoded

Ever found yourself staring at a jumble of bolts, wondering if that metric bolt will work with a standard nut? You're not alone. Understanding the difference between metric and standard (also known as SAE or Imperial) bolts is a crucial skill for anyone working with hardware, from DIY enthusiasts to professional mechanics. This guide will break down the key distinctions, help you differentiate between the two systems, and ensure you always pick the correct fastener.

The world of fasteners can be confusing, especially when dealing with two different measurement systems. Why are there two systems anyway? Historically, the United States adopted the SAE system, while most of the world standardized on the metric system. This difference persists in many industries, leading to the need to differentiate and often compare metric and standard bolts. Identifying the correct bolt type is vital for safety and functionality, as using the wrong bolt can lead to project failure or even dangerous situations.

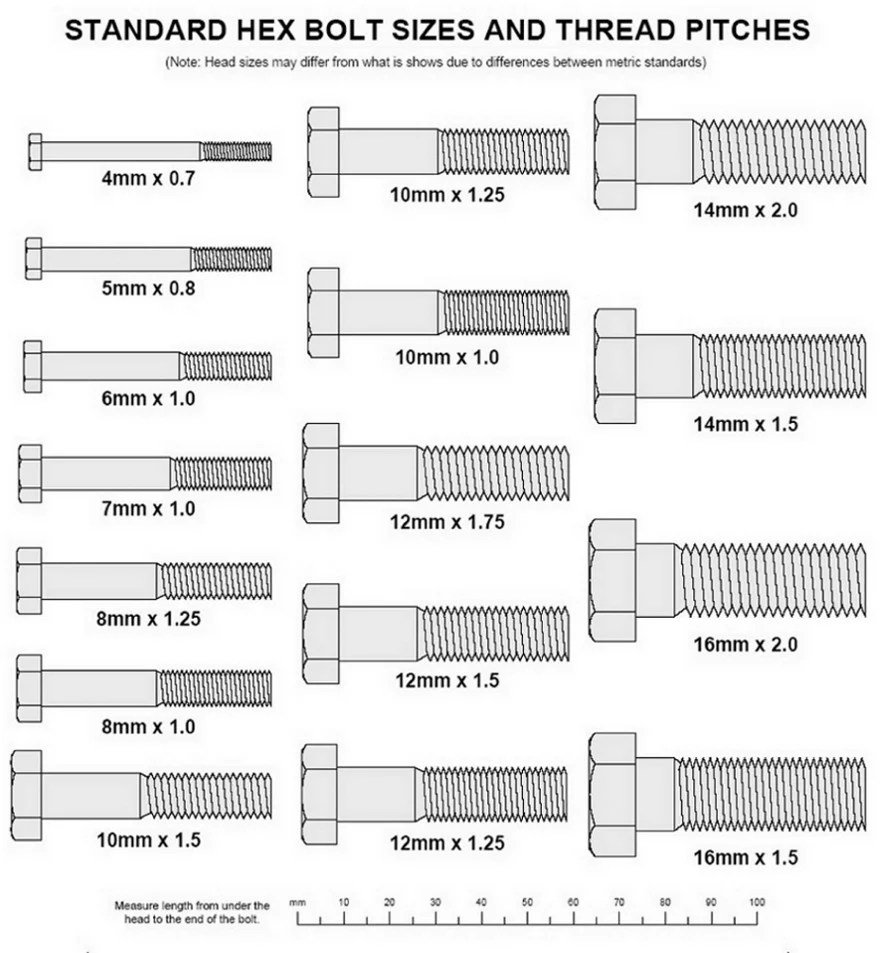

The core difference lies in the measurement units. Metric bolts are measured in millimeters, while standard bolts use inches and fractions thereof. This fundamental distinction affects the thread pitch (the distance between threads), the head size, and the overall bolt dimensions. It's not just about the numbers; the thread profile itself is different. Metric threads are typically finer and have a more rounded profile compared to the coarser, flatter profile of standard threads.

Understanding these differences is essential for successful projects. Imagine trying to force a standard bolt into a metric nut – the threads won’t mesh correctly, potentially stripping the threads or causing a weak connection. This incompatibility highlights the importance of accurately identifying and comparing metric and standard bolts before use.

One common issue is determining whether a bolt is metric or standard. While calipers can provide precise measurements, a quick visual inspection can often suffice. Metric bolts typically have markings indicating their strength class (e.g., 8.8, 10.9), while standard bolts may have radial lines on the head. However, the most reliable method is to measure the thread pitch and diameter using appropriate tools, such as a thread pitch gauge or calipers, and consult a bolt size chart.

One benefit of understanding both systems is the ability to substitute when necessary. While not ideal, there are instances where a close metric equivalent can stand in for a standard bolt, or vice versa. However, this should only be done in non-critical applications and with careful consideration of the load requirements. Always prioritize using the correct fastener for the job.

Another advantage is improved communication. Knowing how to discuss bolt sizes in both systems allows you to collaborate effectively with colleagues, suppliers, and clients worldwide, regardless of their preferred measurement system. This enhanced communication streamlines projects and reduces the risk of misunderstandings.

A simple trick for differentiating between metric and standard fasteners is the “wrench test.” If a standard wrench fits snugly, it’s likely a standard bolt. If it’s a loose fit, try a metric wrench. This method isn't foolproof, but it can be a helpful starting point.

Advantages and Disadvantages

| Feature | Metric | Standard |

|---|---|---|

| Measurement | Millimeters | Inches/Fractions |

| Thread Profile | Finer, rounded | Coarser, flatter |

| Global Availability | Wider | Primarily North America |

Frequently Asked Questions:

1. Are metric and standard bolts interchangeable? Generally, no. Their thread profiles are different.

2. How can I tell if a bolt is metric or standard? Measure the thread pitch and diameter.

3. What is thread pitch? The distance between threads.

4. Where can I find a bolt size chart? Online or at hardware stores.

5. Can I use a metric nut with a standard bolt? No, they are not compatible.

6. What are the common grades of metric bolts? 8.8, 10.9, 12.9 are examples.

7. What are the common grades of standard bolts? Grade 2, Grade 5, Grade 8 are examples.

8. What are the markings on metric bolts? Strength class and manufacturer markings are often present.

In conclusion, distinguishing between metric and standard bolts is essential for any project involving fasteners. Understanding the differences in measurement, thread profiles, and markings ensures proper assembly and prevents potential safety hazards. While quick identification methods like the “wrench test” can be useful, accurate measurement using appropriate tools is always recommended. By familiarizing yourself with both systems, you’ll be better equipped to handle any project, communicate effectively with others in the field, and choose the right fastener every time. Investing a little time in learning about metric and standard bolts will save you headaches and potential problems down the road. So, the next time you're faced with a pile of bolts, you'll be ready to tackle the task with confidence, knowing you have the knowledge to choose the correct fastener for a successful and safe outcome.

Deconstructing the bulge war map

Decoding outboard motor lifespan your guide to longevity

Sherwin williams medium gray the undisputed king of neutral paint