Front Axle Nut Torque Specs: Your Ultimate Guide to a Secure Ride

Ever wonder what that seemingly insignificant nut holding your front axle in place actually does? It’s more than just a piece of metal; it's a crucial component ensuring your wheels stay put. Ignoring its proper tightening, specifically the front axle nut torque specs, can lead to a world of hurt, from annoying vibrations to catastrophic wheel detachment. So, let’s dive deep into the nitty-gritty of front axle nut torque specifications and why they’re so damn important.

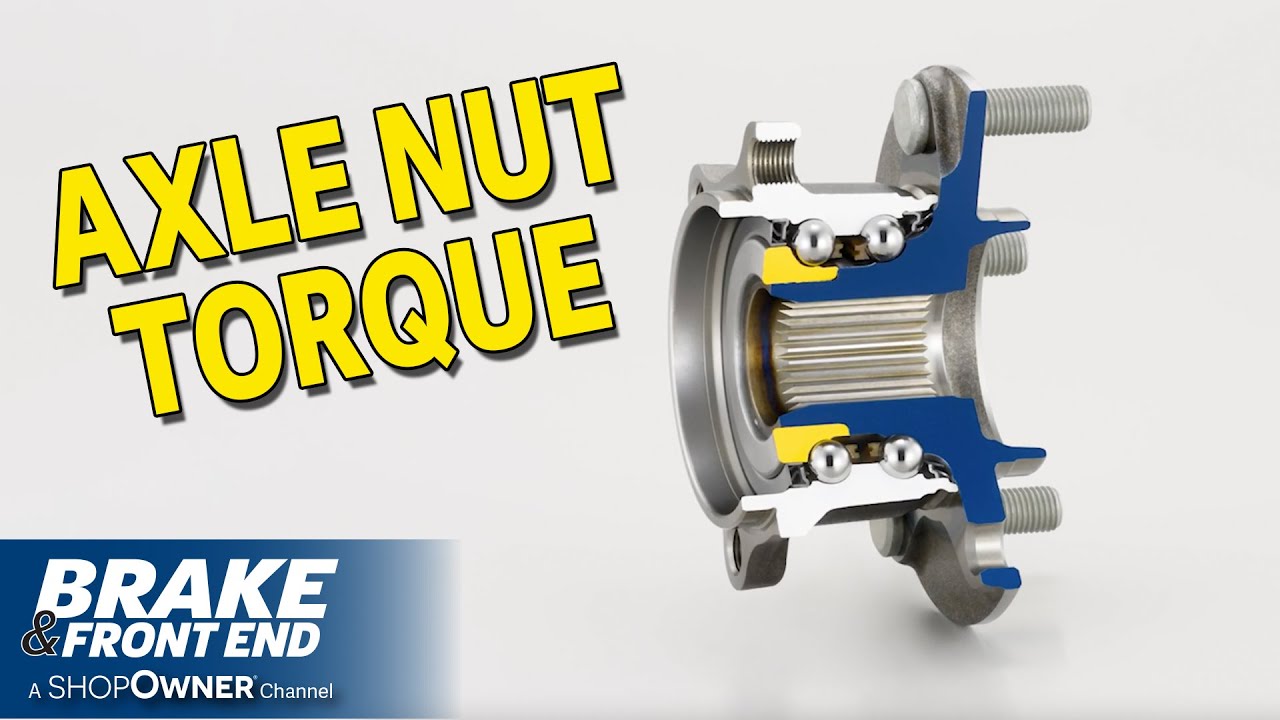

Proper front axle nut tightening, guided by the manufacturer’s specified torque, is paramount for vehicle safety and performance. These torque values are meticulously engineered to ensure the axle is secured firmly without causing damage to the threads or surrounding components. Over-tightening can warp rotors, strip threads, or even lead to premature bearing failure. Under-tightening, however, is equally dangerous, as it can cause the nut to loosen, resulting in wheel wobble, vibration, and potential separation.

The concept of torque isn't new. It's a fundamental principle in mechanics, representing rotational force. Specifically, for our front axle nut, the torque spec dictates the precise rotational force needed to achieve the optimal clamping force. This clamping force secures the axle, ensuring it can handle the stresses and strains of everyday driving and beyond. Historically, torque specifications have evolved alongside automotive engineering, becoming increasingly precise with advancements in materials and manufacturing processes.

The importance of adhering to the correct front axle nut torque cannot be overstated. It's a matter of safety, preventing potential accidents caused by loose wheels. Moreover, correct torque application extends the lifespan of related components, preventing costly repairs down the line. Neglecting these seemingly minor details can translate to significant expenses and safety risks.

One of the main issues surrounding front axle nut torque specs is the lack of awareness among DIY enthusiasts. Many assume tightening “until it feels tight” is sufficient, which is a recipe for disaster. Another common problem is the use of incorrect tools. Using a standard wrench without a torque wrench makes it virtually impossible to achieve the precise torque required, increasing the risk of over or under-tightening.

Front axle nut torque specifications are expressed in units of force multiplied by distance, typically foot-pounds (ft-lbs) or Newton-meters (Nm). These values are vehicle-specific and can be found in the owner's manual or repair guides. For instance, a specific car model might require a front axle nut torque of 150 ft-lbs. This means you need to apply 150 pounds of force at a one-foot radius to tighten the nut correctly.

Benefit 1: Enhanced Safety - Correct torque prevents wheel detachment. Example: A properly torqued axle nut ensures the wheel stays securely attached during high-speed driving, preventing accidents.

Benefit 2: Extended Component Life - Prevents damage to bearings and rotors. Example: Avoiding over-tightening prevents rotor warping and extends bearing life, saving on costly replacements.

Benefit 3: Improved Vehicle Performance - Reduces vibrations and wobble. Example: Correctly torqued axle nuts ensure smooth and stable handling, minimizing vibrations and improving overall vehicle performance.Action Plan: 1. Locate your vehicle's torque specifications. 2. Gather the necessary tools (torque wrench, socket). 3. Follow the proper tightening procedure. Successful Example: A DIYer successfully tightens their front axle nut to the correct torque after consulting their owner's manual, resulting in a smooth and safe driving experience.

Checklist: 1. Correct Torque Spec Identified? 2. Appropriate Torque Wrench Available? 3. Socket Size Correct? 4. Thread Cleanliness Checked?

Step-by-step Guide: 1. Clean the axle threads. 2. Install the new nut. 3. Use a torque wrench to tighten to the specified value. 4. Double-check the torque.

Advantages and Disadvantages

| Advantages | Disadvantages |

|---|---|

| Enhanced Safety | Requires specific tools |

| Increased Component Longevity | Potential for over/under tightening if done incorrectly |

Best Practices: 1. Always consult the owner’s manual. 2. Use a calibrated torque wrench. 3. Clean the threads. 4. Tighten in stages. 5. Double-check the torque.

Examples: (Provide 5 specific car models and their respective torque specs)

Challenges and Solutions: (Provide 5 examples of challenges related to torque specs and their solutions)

FAQ: (Include 8 frequently asked questions and answers related to torque specs)

Tips and Tricks: Lubricate the threads before tightening. Use a high-quality torque wrench. Double-check your work.

In conclusion, understanding and applying the correct front axle nut torque specs is crucial for vehicle safety, performance, and longevity. It's not a task to be taken lightly, as improper tightening can have serious consequences. From preventing wheel detachment to extending component life, the benefits of proper torque application are undeniable. By following the manufacturer’s guidelines, using the correct tools, and adhering to best practices, you can ensure a safe and reliable driving experience while maximizing the lifespan of your vehicle's components. Don't gamble with your safety; take the time to get it right. Consult your owner's manual, invest in a quality torque wrench, and follow the proper procedures. Your vehicle, and your safety, will thank you for it.

Crafting the perfect pls donate stand a guide to guilt tripping i mean fundraising

Exploring the world of genshin impact 3d h a comprehensive guide

Decoding the toyota rav4 hybrid powertrain efficiency meets performance