Decoding Your Wheel Bolt Pattern: A Comprehensive Guide

Ever wondered what those mysterious numbers on your wheel specs mean? That’s your wheel bolt pattern, and knowing how to decipher it is crucial for a safe and proper wheel fit. Choosing the wrong bolt pattern can lead to vibrations, damage, and even wheel detachment – a scenario no driver wants to encounter. This guide will equip you with the knowledge to confidently measure your wheel bolt pattern, ensuring a smooth ride and peace of mind.

Understanding your wheel bolt pattern is like having the right key for your car. It ensures compatibility and secure attachment. Essentially, it describes the arrangement of the lug holes on your wheel hub. It’s usually expressed as two numbers: the number of lug holes and the diameter of the circle on which they’re located (pitch circle diameter or PCD). For example, a 5x114.3 bolt pattern means there are 5 lug holes arranged on a circle with a diameter of 114.3 millimeters.

The standardization of wheel bolt patterns emerged with the rise of mass-produced automobiles. Before this, wheels were often custom-made for each vehicle, making replacements difficult and expensive. A standardized system simplified manufacturing, repair, and the aftermarket wheel industry. Accurate measurement of these patterns became crucial for ensuring interchangeability and safety. A mismatched bolt pattern can lead to serious consequences, highlighting the importance of understanding how to determine your vehicle's specific pattern.

A primary issue related to determining your wheel bolt pattern is misidentification. Many patterns appear similar at a glance, leading to incorrect measurements and potential incompatibility. This can be exacerbated by corrosion or damage to the wheel hub, making accurate measurement challenging. Another issue is the variety of measuring systems (metric and imperial) used for different vehicles, requiring careful attention to units.

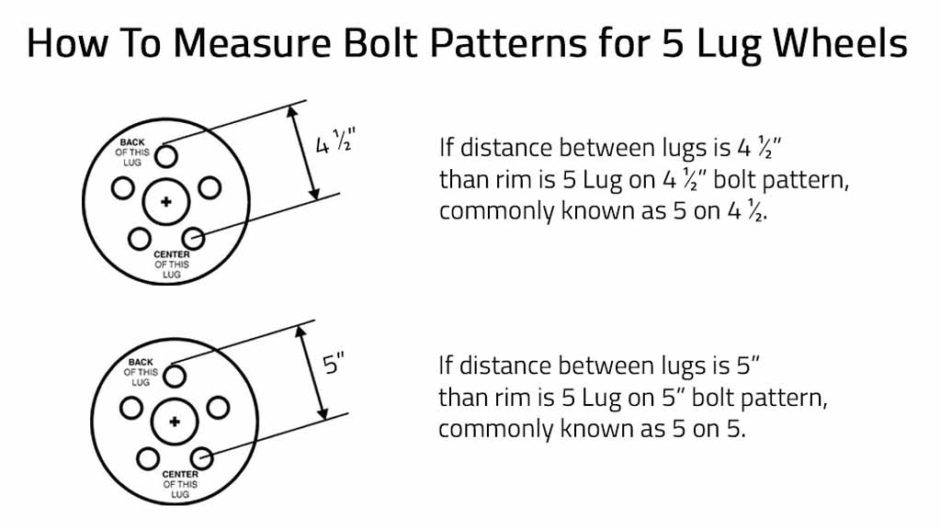

Let's explore how to identify your wheel bolt pattern. For wheels with an even number of lugs (4, 6, 8), measure from the center of one lug hole directly across to the center of the opposite lug hole. This is your PCD. For wheels with an odd number of lugs (5, 7), the process is slightly different. You’ll need to measure from the back edge of one lug hole to the center of the opposite lug hole. Then, consult a bolt pattern chart or use an online calculator to determine the PCD based on this measurement and the number of lugs.

One benefit of knowing your wheel bolt pattern is the ability to explore aftermarket wheel options. You can widen your choices and customize your vehicle's appearance without compromising safety. Secondly, correctly identifying your bolt pattern ensures proper wheel fitment, preventing vibrations and potential damage. Finally, it simplifies the wheel replacement process. You'll be able to quickly find compatible replacements, saving time and frustration.

Step-by-step guide:

1. Remove one wheel from your vehicle.

2. Count the number of lug holes.

3. Measure as described above (even vs. odd number of lugs).

4. Record your measurements.

5. Compare your findings with a bolt pattern chart or use an online calculator to confirm the PCD.

Frequently Asked Questions:

1. What if my wheel is damaged? Try to find a clean area for measurement. If the hub is damaged, consult a professional.

2. Can I use a tape measure? Yes, but a caliper provides more accurate measurements.

3. What if I can't find my bolt pattern on a chart? Consult your vehicle's owner’s manual or contact a dealer.

4. Are there different measuring systems? Yes, both metric (mm) and imperial (inches) are used.

5. Why is my steering wheel vibrating after installing new wheels? A mismatched bolt pattern could be the culprit.

6. Can I change my car's bolt pattern? It's generally not recommended and requires significant modifications.

7. Where can I find a reliable bolt pattern chart? Many online resources and automotive forums provide these charts.

8. What's the difference between lug nuts and bolts? Lug nuts secure the wheel to the studs on the hub, while lug bolts thread directly into the hub.

Tips and Tricks

Clean the hub surface for accurate measurements. Double-check your measurements to avoid errors. If uncertain, consult a professional.

Knowing how to measure your wheel bolt pattern is essential for maintaining your vehicle's safety and performance. This seemingly small detail plays a significant role in ensuring a smooth and secure ride. By understanding the measurement process, common patterns, and potential issues, you can avoid costly mistakes and ensure proper wheel fitment. Taking the time to accurately determine your bolt pattern empowers you to make informed decisions when replacing or upgrading your wheels, ensuring compatibility and a safe driving experience. Don't underestimate the importance of this crucial measurement – it's the foundation of a stable and reliable connection between your vehicle and the road. Consult with a professional if you are still unsure, and always prioritize safety when making modifications to your vehicle.

Clean furnace drain line ensuring efficient heating

Decoding sherwin williams versatile gray the ultimate guide

Banned books the forbidden index explained