Decoding the Nuances Between Metric and Imperial Bolts

Imagine stumbling upon a beautifully crafted vintage motorcycle, its intricate details whispering stories of bygone eras. Suddenly, you realize a bolt needs replacing. This is where the seemingly simple world of fasteners becomes surprisingly complex. Is it a metric or an imperial bolt? The answer is far more critical than you might initially think. Mismatched bolts can lead to stripped threads, compromised structural integrity, and ultimately, a less functional, less beautiful machine.

This seemingly subtle difference between metric and imperial bolts underpins much of how we build and maintain everything from bicycles to bridges. Understanding this distinction isn’t just for mechanics and engineers; it’s essential knowledge for anyone working with tools and hardware. Think of it as the silent language of construction, a subtle code that determines how parts fit together, and how well they hold.

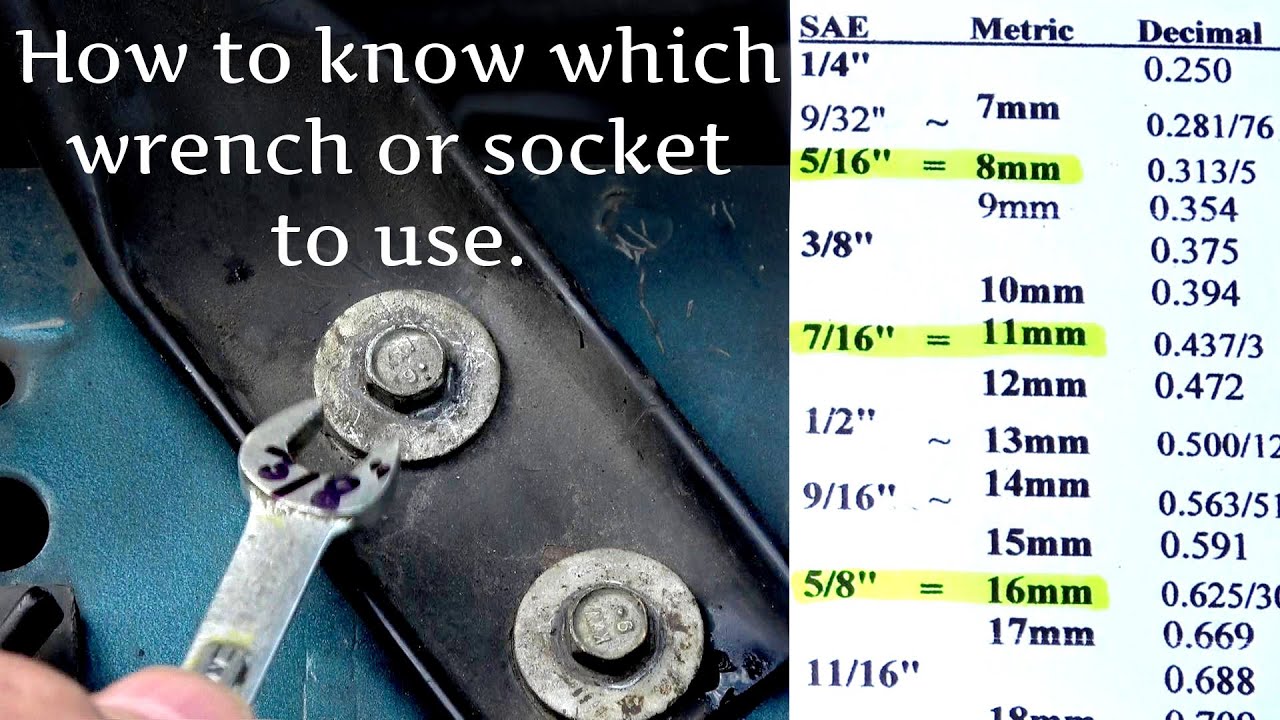

The difference fundamentally boils down to their measurement systems. Metric bolts, as the name suggests, adhere to the metric system, employing millimeters for diameter and thread pitch. Imperial bolts, on the other hand, utilize inches and threads per inch, a legacy of the British Imperial system. This seemingly minor variance has profound implications for compatibility and interchangeability.

Historically, the imperial system dominated manufacturing, particularly in the United States and parts of the British Commonwealth. However, the global shift towards the metric system has seen a corresponding rise in the prevalence of metric fasteners. Recognizing which system you're dealing with is crucial for avoiding costly mistakes and ensuring the structural soundness of any project.

One of the initial challenges lies in visually distinguishing between the two. While some differences can be discerned with the naked eye, such as thread coarseness and head markings, relying solely on visual cues can be misleading. Accurate identification requires careful measurement using appropriate tools like calipers or thread gauges. This meticulous approach becomes even more critical when dealing with older or less commonly encountered fasteners.

The importance of understanding the difference between metric and imperial bolts goes beyond simple compatibility. It's a matter of safety and reliability. Using the incorrect bolt can lead to weakened joints, potentially resulting in equipment failure or even injury. Imagine the consequences of a mismatched bolt in a critical component of an airplane or a car.

A key element in identifying metric bolts is their thread pitch, the distance between threads. This is often finer in metric bolts compared to their imperial counterparts. Imperial bolts are usually identified by fractions of an inch, while metric bolts utilize whole numbers representing millimeters. This distinction becomes clear when using a thread pitch gauge, an essential tool for accurately identifying and matching bolts.

One benefit of recognizing the difference is the ability to source the correct replacement parts, preventing frustration and delays in projects. Another benefit is ensuring the integrity and safety of assembled components, reducing the risk of failure due to incompatible hardware. Finally, understanding both systems enhances overall technical knowledge and professionalism, allowing for more efficient and effective work.

Advantages and Disadvantages of Metric and Imperial Bolts

| Feature | Metric | Imperial |

|---|---|---|

| Measurement System | Metric (millimeters) | Imperial (inches) |

| Global Prevalence | More common internationally | More common in the US and some parts of the former British Commonwealth |

| Thread Pitch | Generally finer | Generally coarser |

| Tool Availability | Widely available globally | Readily available in countries using the imperial system |

One real-world example highlighting the importance of this distinction involves a classic car restoration. Using metric bolts on an imperial system vehicle could strip the threads, compromising the structural integrity and ultimately devaluing the vehicle. Another example involves assembling furniture – using mismatched bolts can result in wobbly joints and eventual collapse. Industrial machinery, aerospace engineering, and construction all rely on the precise matching of bolts to ensure safety and functionality.

A common challenge is identifying worn or corroded bolts. Solutions include using thread gauges or consulting with experienced machinists. Another challenge is sourcing less common bolt sizes. Solutions involve specialist suppliers or online retailers. A third challenge is converting between metric and imperial sizes. Online calculators and conversion charts provide reliable solutions.

Frequently Asked Questions:

1. What's the primary difference between metric and imperial bolts? Answer: The core difference is their respective measurement systems – metric uses millimeters, while imperial uses inches.

2. How can I tell them apart? Answer: Use a thread gauge or caliper for accurate measurement.

3. Can I mix metric and imperial bolts? Answer: Generally no, as it can compromise the integrity of the connection.

4. What are the markings on bolt heads? Answer: Markings indicate grade and strength.

5. Where can I find metric/imperial bolts? Answer: Hardware stores, online retailers, and specialist suppliers.

6. What tools do I need? Answer: Wrenches, sockets, and thread gauges are essential.

7. Why are there two systems? Answer: Historical reasons and regional preferences.

8. What if I use the wrong bolt? Answer: It can lead to stripped threads, weakened joints, and potential failure.

A useful tip is to organize your fasteners by type and size, preventing mix-ups and streamlining projects. Another trick is to use magnetic trays to keep bolts from rolling away while working.

In conclusion, understanding the difference between metric and imperial bolts isn’t merely a technical detail; it's fundamental to ensuring the safety, functionality, and longevity of anything we build or repair. From the seemingly mundane task of assembling furniture to the complexities of aerospace engineering, this distinction plays a critical role. By taking the time to identify and use the correct fasteners, we not only enhance the integrity of our work but also contribute to a safer and more efficient world. This seemingly small detail highlights a much broader principle: precision matters. In a world increasingly reliant on intricate systems, the careful consideration of even the smallest components can have significant and far-reaching consequences. Mastering this distinction empowers us to approach any project with greater confidence, knowing that the foundation we build is strong and reliable. So, the next time you pick up a wrench, take a moment to consider the humble bolt – its silent language speaks volumes about the quality and durability of your work.

Elk city lake hiking trails your guide to adventure

Transform your space with large plaster wall art

Unlocking the secrets of boat speed and travel time